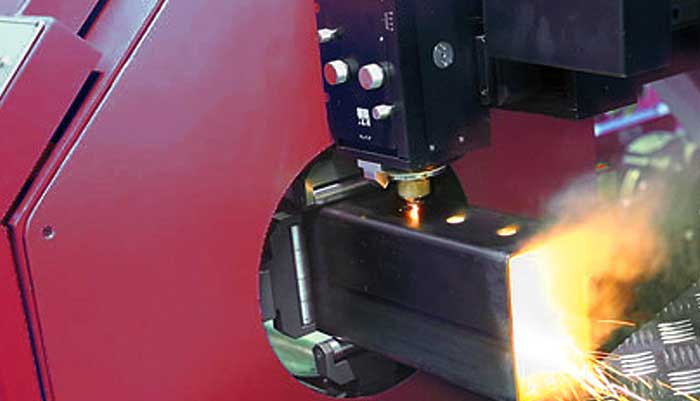

Fiber lasers are capable of cutting thin materials with high speeds. Fiber lasers are very efficient and low in power consumption, but require very little maintenance. Laser cutting technology is able to cut steel, stainless and aluminum as well as nonferrous metals such copper and brass.

Variety is the reality of any job shop, and the same goes for those that operate a tube laser. Itís not unusual to see parts of various sizes come from one tube. The machine must be able to unload laser-cut parts that may be as small as 2 in. and as long as 15 ft., one right after the other. It also must be able to unload those parts without damaging them, which can be a challenge with softer metals such as aluminum.